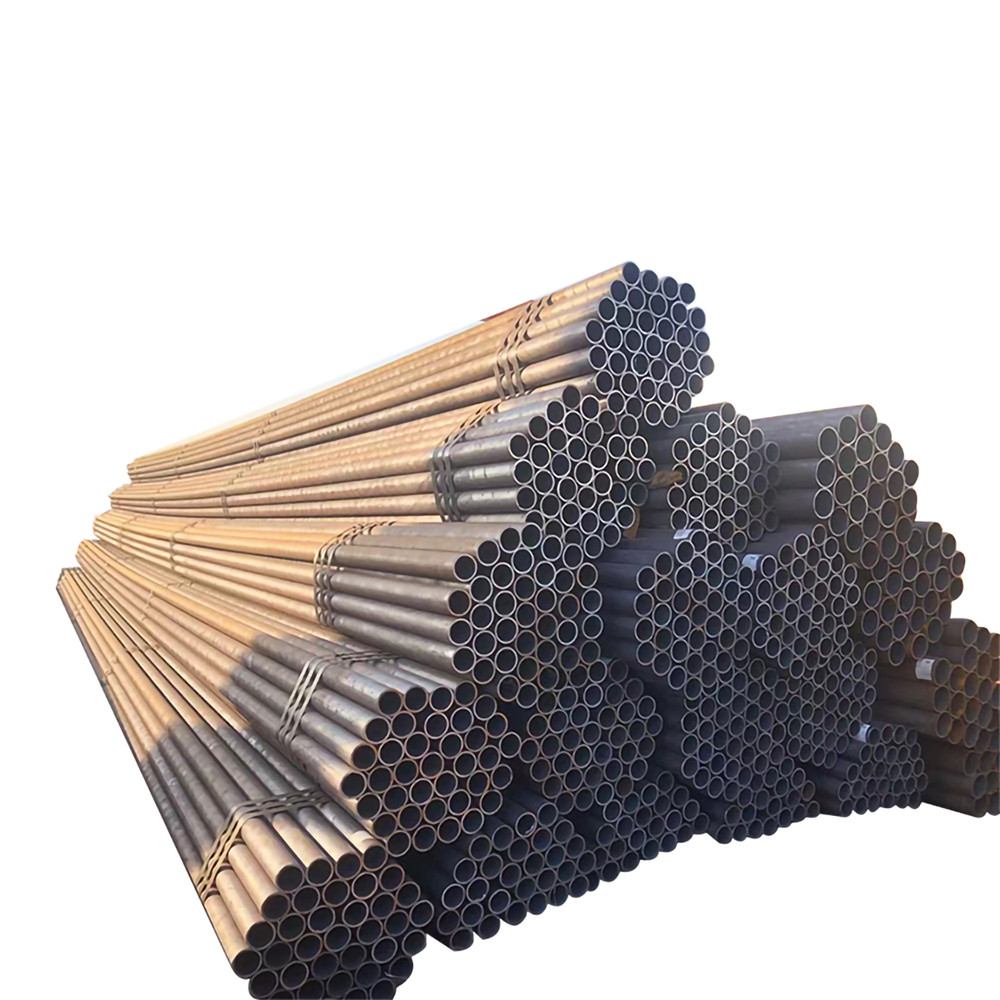

Pipe ea tšepe e sa koaheloang e chesang

Pipe ea tšepe e sa koaheloang e chesang

Sebopeho

-

Hot phuthoa seamless tšepe phala: chesang rolling e amana le batang-rola, e leng o etsoang ka tlas'a recrystallization mocheso, ha chesang rolling o etsoa ka holim'a mocheso recrystallization.

1) Tloaelo: JIS, AISI, ASTM, GB, DIN, EN, ASME

2) Botenya: 1.24 - 36.5 limilimithara

3) Sebopeho sa Karolo:E chitja

4) Kantle Diameter: 38 - 426 limilimithara, ho ea ka tlhokahalo ea bareki

5)Sebaka sa Tšimoloho: Tianjin China (Bohareng)

6) Bobeli Kapa Che: E seng ea bobeli

7) Theknoloji: Hot Rolled

8) Phekolo ea Bokaholimo: Joalo ka kopo ea bareki

9) Ho paka: Pakete e tloaelehileng e loketseng leoatle

10) Alloy Kapa Che: Ha e na alloy

11) Bolelele: 2-12m kapa joalo ka kopo ea bareki

12) Kereiti: Gr.B/X42/X46/X52/X60/X70, joalo-joalo.

13) Boitsebiso: Pipe ea tšepe ea carbon

14) Mofuta: Pipe ea tšepe e cheselitsoeng / e se nang seam

Ho chesa ho ka senya mohaho oa ho lahla oa ingot ea tšepe, ho hloekisa lithollo tsa tšepe le ho felisa mefokolo ea microstructure, e le hore mohaho oa tšepe o be o teteaneng le thepa ea mechine e ntlafatsoa.Ntlafatso ena e bonahala haholo-holo ka tataiso ea ho roala, e le hore tšepe e se e sa le isotropic ho isa tekanyong e itseng;Li-bubble, mapetsong le porosity tse entsoeng nakong ea ho tšela li ka boela tsa chesetsoa tlas'a mocheso o phahameng le khatello.

Tube blank - tlhahlobo - peeling - tlhahlobo - ho futhumatsa - ho phunya - pickling - ho sila - lubrication le ho omisa moea - welding hlooho - batang ho taka - tharollo ea phekolo - pickling - pickling passivation - tlhahlobo - ho pholile hamonate - deoiling - ho itšeha hlooho - ho omisa moea - ka hare. ho bentsha

Lipeipi tsa tšepe tse kentsoeng li arotsoe ka liphaephe tsa tšepe tse akaretsang, liphaephe tsa tšepe tsa khatello e tlase le e mahareng, liphaephe tsa tšepe tse nang le khatello e phahameng, lipeipi tsa tšepe tse sa hloekang, liphaephe tse petsohang tsa peterole, lipeipi tsa tšepe tsa jeoloji le lipeipi tse ling tsa tšepe.

1.Liphaephe tse ngata tse ka tlas'a lefatše li sebelisoa bakeng sa lipalangoang, metsi a ka tlas'a lefatše a ntšoa nakong ea Gai Lou, 'me metsi a chesang a boiler a sebelisoa bakeng sa lipalangoang.

2.Machining, ho jara matsoho, likarolo tsa mochini oa machining, joalo-joalo.

3.Motlakase: phetisetso ea khase le phaephe ea mokelikeli oa motlakase oa metsi.

4.Anti-static tubes ea limela tsa matla a moea.

Kopo

Joalo ka indasteri ea thepa ea tšepe ea China e etellang pele likhoebo, khoebo ea naha ea tšepe le thepa "khoebo ea tumelo e ntle e makholo", likhoebo tsa khoebo tsa tšepe tsa China, "Likhoebo tse phahameng tsa 100 tsa Shanghai". ) e nka" Integrity, Practicality, Innovation, Win-Win " e le eona feela molao-motheo oa ts'ebetso, e lula e phehella ho beha tlhoko ea bareki sebakeng sa pele.

- BOTS'EPEHI

- HLOKOMELA

- PRAGMATIKI

- TS'OANELO MOTS'OANE